Algae Plastic Replacement: Unlocking the Potential of A Revolutionary Eco-Friendly Solution

Can algae-derived materials truly replace conventional plastics? Let’s talk algae plastic replacement potential, its production process, and how it represents shift in the future of sustainable resources.

Key Takeaways

- Algae plastic replacements offer an eco-friendly, biodegradable alternative to petroleum-based plastics. This give the potential to revolutionize various industries and help reduce reliance on non-renewable resources.

- Plastic pollution poses significant environmental and human health risks. This makes the development of sustainable alternatives, like algae plastic replacements critical to address the crisis and support public health.

- While showcasing promising applications in reducing plastic waste and in biofuel production, algae plastic replacement faces challenges. These include scalability, cost-effectiveness, and the need for further technological advancements to improve production processes.

Algae Plastic Replacements: A Sustainable Alternative

Algae plastic replacements are emerging as a potent tool in sustainable development. Offering functionality similar to petroleum-based plastics, they bring the added advantage of being environmentally friendly due to their biodegradable nature. This new material, derived from seaweed, has the potential to revolutionize industries from packaging to automotive. This would all be while reducing our reliance on non-renewable sources.

Genetic engineering allows for the making of essential compounds like PHB from algae. These compounds are crucial for the production of advanced bioplastics. Furthermore, the cultivation process of microalgae can be improved with carbon dioxide supplementation, using their photosynthesis ability to increase biomass production. These advancements are paving the way for algae-based bioplastics to counter the global challenge of plastic pollution.

Algae’s Advantages Over Traditional Feedstocks

The advantages of using algae as a feedstock for biofuel production are manifold. Unlike traditional feedstocks, algae cultivation offers the following benefits:

- It requires non-arable land, non-potable saline water, and wastewater, reducing the demand for resource-intensive agricultural inputs.

- Does not contribute to deforestation or displacement of natural ecosystems.

- It does not compete with food production as it doesn’t require fertile soil and can capitalize on wastewater for growth.

Algae exhibit high biomass yields, growing 5-10 times faster than food crops. This significantly enhances their efficiency and potential as a sustainable source of raw materials. Moreover, algae’s ability to grow in various water bodies, including those deemed unsuitable, adds to their rapid growth and high yield with little resource inputs. Algae-based bioethanol production, therefore, stands out as a sustainable and environmentally friendly option.

Types of Algae Plastic Replacements

The versatility of algae extends to the production of various types of bioplastics. Various components of algae biomass, including:

- starch

- cellulose

- protein-based polymers

- polysaccharides

These serve as fundamental elements in bioplastic production. Biodegradable polymers like Polyhydroxyalkanoates (PHAs) and Polyhydroxybutyrates (PHBs) can be produced within the cells of microalgae. This further enhancing the potential of algae-based bioplastics.

The manufacturing of bioplastic composites involves blending microalgal biomass with petroleum or bio-based polymers and additives. This uses techniques like compression molding and melt mixing. This process can be optimized through the incorporation of plasticizers and compatibilizers. This would allow for the creation of tailored properties in bioplastics. As progress continues in genetic engineering and bio-refinery methods, the sustainability of bioplastic manufacturing is expected to improve significantly. This further supports the adoption and potential of algae plastic replacements.

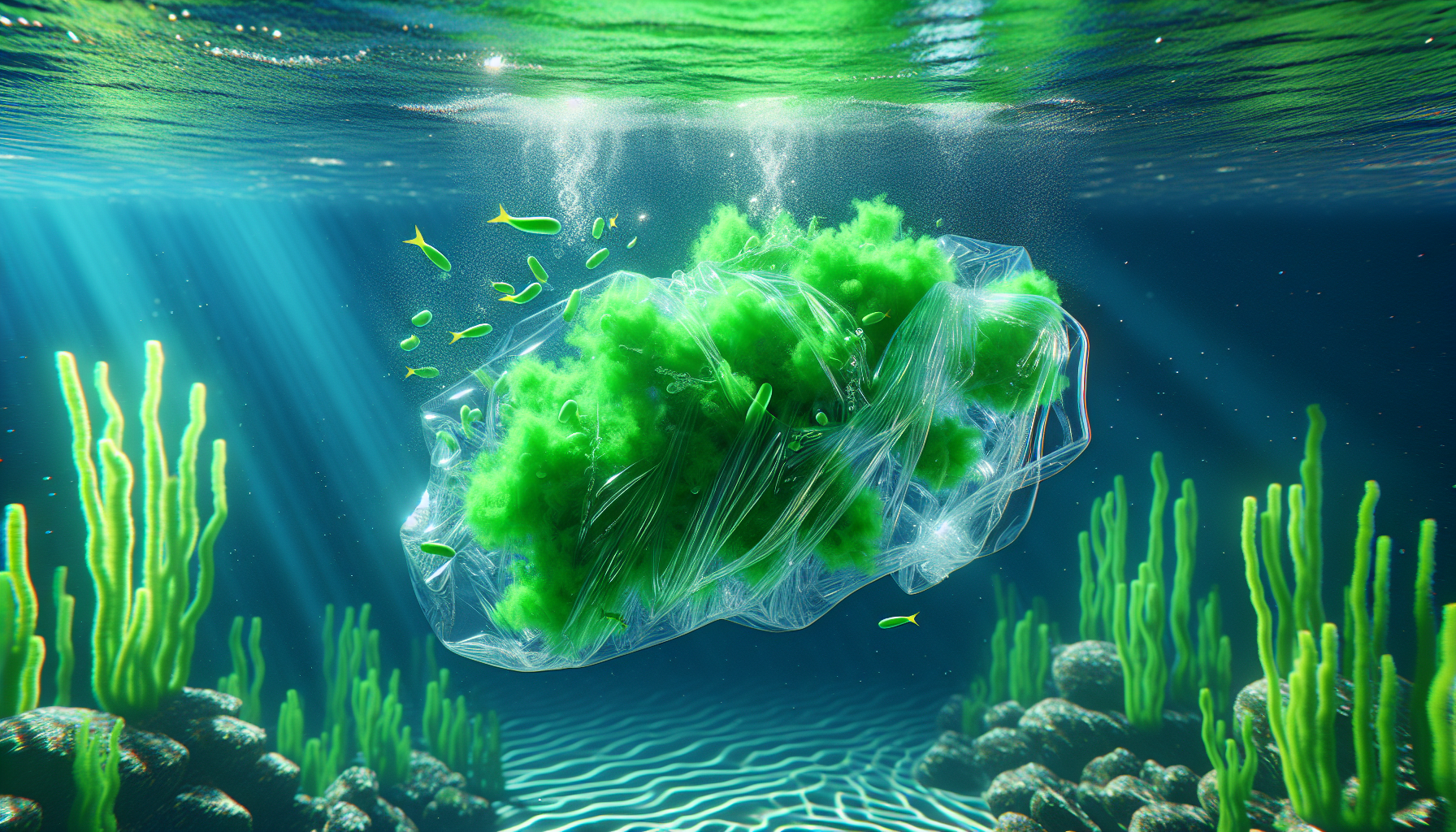

Plastic Pollution Crisis: The Need for Change

The escalating crisis of plastic pollution is a global concern that demands immediate attention. Every year, 19-23 million tonnes of plastic waste leaks into aquatic ecosystems, polluting lakes, rivers, and seas. This pollution alters habitats and natural processes, reducing ecosystems’ ability to adapt to climate change.

Moreover, plastic waste, including plastic films, directly affects millions of people’s livelihoods, food production capabilities, and social well-being. The environmental, social, economic, and health risks of plastics are substantial, demanding urgent attention alongside other environmental stressors such as climate change, ecosystem degradation, and resource use.

The need for sustainable alternatives like algae-based bioplastics, in line with sustainable development goals, has never been more pressing.

Algae Plastic Replacement Start-ups

Several notable companies are at the forefront of transforming seaweed into plastic alternatives. Each of these offer unique solutions and innovations in this emerging field:

- Kelpi: Based in the UK, Kelpi leverages the properties of seaweed to create compostable, marine-safe, low-carbon bioplastic packaging. Established in 2020, Kelpi is making strides in sustainable packaging solutions.

- Notpla: A London-based sustainable packaging company founded in 2014, Notpla has developed advanced packaging solutions from seaweed. Notably, they provided biodegradable water capsules for the 2019 London Marathon. These capsules, called Ooho, are made from seaweed and offer an innovative alternative to single-use plastic.

- Zerocircle: Located in India, Zerocircle focuses on producing wildlife and ocean-safe packaging materials from locally cultivated seaweed. Their products are designed to dissolve in the ocean after use and replace common plastics like LDPE and PP. Founded by Neha Jain, Zerocircle collaborates with large CPG companies to manufacture industrial packaging materials.

- Sway: This US-based company, founded in 2020, offers seaweed-based, biodegradable substitutes for thin-film plastic packaging. Sway’s products include shopping bags and wrapping materials, which decompose within four to six weeks after use.

- Marea: An Icelandic start-up, Marea has developed seaweed biopolymers to create a model for thin-film plastic that fully biodegrades. Julie Encausse, the founder, initiated this project during her university course.

- FlexSea: Founded in London in 2021, is a notable company in the field of seaweed-derived bioplastics. They focus on creating innovative materials to replace single-use plastics.

- ULUU: An Australian startup, ULUU makes a range of natural polymers, PHAs (polyhydroxyalkanoates), using seaweed, seawater, and saltwater microbes. Founded by Michael Kingsbury and Oceanographer Dr. Julia Reisser, ULUU aims to reduce reliance on freshwater by using seawater in its production processes.Human Health Concerns

On Evoware and Loliware

Both Evoware and Loliware are at the forefront of innovation in creating sustainable alternatives to traditional plastics. Both are optimizing the unique properties of seaweed to develop products that are environmentally friendly and biodegradable.

Evoware, co-founded by David Christian, is a sustainability-focused company that specializes in creating eco-friendly alternatives to single-use plastics. Their product range includes plastic-free bags made from cassava, disposable straws from rice, and cups and wrappers made from seaweed. Evoware has a vision to prevent environmental damage from single-use plastics and empower individuals and businesses to switch to sustainable materials, such as algae plastic replacements. They have gained recognition globally and have a distribution presence in countries like Indonesia, Australia, and Saudi Arabia.

On the other hand, Loliware is known for its innovative AI-driven seaweed biomaterials. Their patented Sea Technology resins are a new category of resins made from regenerative, carbon-capturing, ocean-farmed seaweed. Loliware’s products include the Blue Carbon Straw, which is fully commercialized and verified as plastic-free. The company emphasizes the environmental benefits of seaweed, such as fighting climate change, contributing to healthy oceans and soil, and being a tree-free and regenerative option for packaging. Loliware’s products are designed to disappear, aligning with the goal of advancing a plastic-free future.

The need for sustainable alternatives like algae plastic replacements are not just an environmental necessity, but a public health imperative.

Algae’s Role in Plastic Biodegradation

Algae are a critical component in the natural biodegradation of plastic. They secrete enzymes that are key in breaking down plastic polymers, initiating the biodegradation process. Algae’s colonization on plastic surfaces is a natural phenomenon that marks the initiation of the plastic biodegradation process.

In marine habitats, where most plastic waste accumulates, algae do not require organic carbon sources, making them an efficient biological agent for biodegradation of plastics in these environments. The interaction between algal enzymes and plastic polymers triggers the biodegradation process, with algae promoting the breakdown of polymers by weakening the chemical bonds in the polymer, using them as carbon sources. Through enzyme production and colonization on plastic surfaces, algae offer a natural solution to reduce plastic waste in the environment.

Enzymatic Breakdown of Plastics

The biodegradation of plastics by algae is a process in which enzymes produced by the algae interact with plastic polymers, causing them to break down. Enzymes such as cutinase, lipase, and esterase have been identified for their ability to degrade synthetic oligomers or polymers by weakening the plastic’s chemical bonds.

Through genetic modification techniques, microalgae can be transformed into microbial cell factories that produce and secrete increased amounts of plastic-degrading enzymes. This enzymatic breakdown of plastics by algae leads to the transformation of plastic waste into metabolites such as water, carbon dioxide, and new biomass, mitigating environmental impact and contributing positively to ecological cycles.

Algae Colonization on Plastic Surfaces

Algae can colonize artificial substrates such as polythene surfaces in various environments, including sewage water, and these algae are typically non-toxic. The colonization process by microalgae on microplastics varies over time, typically stabilizing in mature biofilms, and is influenced by environmental factors like:

- temperature

- light

- oxygen

- moisture

Microplastics in aquatic environments create new niches that invite colonization by diverse microalgae communities, which do not show specificity to particular plastic polymers. Surface degradation is evident on the transverse sections of algal-colonized polyethylene sheets. Specific algae species, such as Anabaena spiroides, significantly degrade polyethylene, and nontoxic freshwater cyanobacteria like Phormidium lucidum are able to biodegrade polyethylene efficiently without pre-treatment.

Biofuel Production from Algae

Another promising area of research is the production of biofuel from algae. Certain strains of microalgae contain oil content up to 80% by dry weight and can rapidly reproduce, making them prolific sources for biofuel production. Algal biofuel production primarily uses photobioreactors and open pond systems, with photobioreactors providing higher biomass productivity, albeit with higher costs and scalability challenges. The National Renewable Energy Laboratory is actively researching these methods to optimize the process.

The process of harvesting microalgae involves techniques such as gravity settlement or centrifugation, followed by oil extraction through solvent extraction methods. However, the cost-effectiveness of algae-based oil production heavily relies on petroleum prices; it needs to cost below $2.59/gallon to compete with a petroleum price of $100/barrel. As research continues, innovative conversion technologies like hydrothermal liquefaction are being explored for enhancing the conversion of wet algal biomass into biocrude, which could streamline the algae to biofuel pipeline.

Cellulosic Ethanol

Cellulosic ethanol production from cellulosic biomass, such as algae, is an emerging field that offers potential advantages over oil extraction for biodiesel. Both microalgae and macroalgae can be used to convert biomass for bioethanol production due to their starch reserves and cellulose in cell walls, suitable for yeast fermentation.

Specific types of green microalgae, such as Chlamydomonas reinhardtii, Chlorococcum humicola, and Chlorella vulgaris, are notable for their high starch/glucose content and are considered for cellulosic ethanol production. The pretreatment process for converting algae biomass to glucose for fermentation involves steps like liquefaction using alpha-amylases and subsequent saccharification with amyloglucosidase.

Algae cell walls, particularly from certain strains with low lignin and hemicellulose content, are being looked at as third-generation bioethanol feedstocks due to their easier processing for ethanol production.

Algae Biodiesel

Algae-derived biodiesel is another sustainable alternative to fossil fuels, including petroleum diesel. This renewable fuel, classified as one of the liquid biofuels, is derived from the lipid component of microalgae, specifically tricylglycerols, through a process of transesterification to form fatty acid methyl esters (FAME), constituting the chemical structure of biodiesel. As a result, algae-derived biodiesel is considered a promising option among liquid fuels.

Optimal oil production in microalgae for biodiesel is influenced by factors such as:

- Nutrient availability, particularly nitrogen levels

- Light intensity

- Temperature

- Salinity

These factors can impact the microalgae’s growth and lipid synthesis. However, harvesting oil from microalgae for biodiesel production poses challenges due to the organisms’ small cell size. Techniques such as flocculation, flotation, and centrifugation are used for efficient biomass separation.

Despite these challenges, the potential of algae as a biodiesel source is underscored by its higher oil yield compared to traditional crops and the feasibility of an integrated biorefinery approach, which can bolster both the economic viability and environmental sustainability of microalgal biofuel production.

Challenges and Future Prospects of Algae Plastic Replacements

Despite the immense potential of algae-based bioplastics and biofuels, several significant challenges remain to be addressed. The production of algae-based bioplastics currently faces economic challenges like high costs and need for substantial infrastructure development, which result in lower competitiveness compared to conventional plastics. Technological advancements and innovations, including CRISPR–Cas9, are key to improving the economic feasibility of algae bioplastics, yet these technologies are still in early stages and require further research and development.

Researchers also need to address significant challenges in selecting suitable algae strains and managing harmful emissions during bioplastic production to ensure sustainable production that meets environmental standards. Optimization of the algae-based bioplastic production process is essential for scaling up to commercial levels to meet the growing demand for sustainable materials.

Future research should target:

- The development of supportive legislation

- Public education

- Bioengineering techniques to enhance market acceptance

- Improve production methodologies for algae-based bioplastics.

Identifying Suitable Algae Strains

One key challenge in the production of algae plastic replacements is the selection of suitable algae strains. High yields of bioplastic precursors are required, making the selection process challenging. However, advanced biotechnological tools, including genetic engineering and CRISPR-Cas9, are pivotal in developing tailored microalgae strains.

Through genetic modifications, microalgae can be optimized to produce increased levels of bioplastic precursors such as PHA and PHB, which are essential for bioplastic production. As research in this area continues, the identification and optimization of suitable algae strains are expected to become more efficient and effective.

Algae to Clean Up Air Pollution

Chinese scientists are actively using algae to combat air pollution, a project led by the Chinese Academy of Sciences’ Institute of Hydrobiology. This innovative approach involves developing a new strain of microalgae that shows high efficiency in consuming nitrogen oxides, a major component of smog. The efficiency of these microalgae in reducing nitrogen oxides can reach up to 96%.

This method not only reduces industrial emissions in an environmentally friendly and cost-effective way but also generates algae biomass. This biomass can be used and sold, and importantly, it can be processed into biofuel, fish feeds, fertilizers, health supplements, and a range of other products. The algae-based cleansing method is safer, requires less energy than traditional methods, and produces valuable by-products.

Real-World Applications and Innovations of Algae Plastic Replacements

Algae plastic replacements and biofuels have transcended the realm of theoretical concepts and are already in real-world use. Algae plastice replacements are currently used in packaging materials and disposable items due to their biodegradability and lower environmental impact compared to traditional plastics. Research and development in biofuel production from algae have led to the creation of bioethanol and biodiesel, which are now being tested as renewable fuels in various transport sectors.

In the automotive industry, there is increasing interest in using algae bioplastics for car parts and interiors to reduce vehicle weight and thus improve fuel efficiency. Algae-derived biofuels have the potential to reduce greenhouse gas emissions significantly when used in land, sea, and air transport, offering a sustainable alternative to fossil fuels.

Consumer Products

Algae plastic replacements offer eco-friendly solutions for the packaging industry due to their biodegradability, contributing to the reduction of plastic pollution. Innovators like Ari Jónsson have developed algae-based bottles that biodegrade when empty, challenging the disposable bottle market with a sustainable alternative. Eric Klarenbeek and Maartje Dros established AlgaeLab, creating starch-based bioplastic products from algae, demonstrating the substitution potential for traditional plastics.

Even toys and other consumer items can be created from bioplastics derived from microalgae species such as Chlorella, Spirulina, and Nannochloropsis. Algae-based bioplastics are proving to be a viable and sustainable alternative for a range of consumer products.

Single Use Plastic and Packaging Replacement

Algae plastic replacements present a sustainable alternative to single-use plastics. These biodegradable materials can be used in a variety of applications, similar to conventional plastics. For instance, small bags for packaging food items, shopping bags, and even plastic packing that is custom-molded to fit products can be made from algae-derived materials. This flexibility in use, combined with their eco-friendly nature, makes them a promising solution for reducing plastic waste. By replacing petroleum-based plastics with algae-based ones, we can significantly decrease the environmental impact associated with single-use plastics.

Transportation

Algae-based biofuels have the potential to revolutionize the transportation sector. Some benefits of algae-derived biodiesel include:

- They offer a sustainable alternative to power vehicles

- Optimizes high lipid content microalgae

- Does not compete with food sources

- It can be optimized for enhanced lipid production

The aviation industry is actively investing in algae-based biofuels for aircraft with the support of several airlines and stakeholders, aiming to increase adoption rates in line with the International Air Transport Association’s goal of 2% biofuel use by 2025. Algae-based biofuels, particularly as sustainable aviation fuel (SAF), can significantly reduce the carbon footprint of aviation with the potential to lower CO2 emissions by 20-98% compared to conventional jet fuel. Algae-based biofuels have been contributing to greener aviation since 2011, marking the beginning of an industry shift towards more sustainable flight practices.

Summary

In conclusion, the potential of algae plastic replacements and biofuels is immense. Offering a sustainable alternative to petroleum-based plastics and fuels, they promise a future where our reliance on non-renewable resources is significantly reduced. While challenges exist in terms of production costs and scalability, ongoing research and technological advancements offer hope for overcoming these hurdles. As we continue to innovate and push the boundaries of green technologies, it’s clear that algae plastic replacements and biofuels will play a critical role in our journey towards a sustainable future.

Frequently Asked Questions on Algae Plastic Replacements

Can algae replace plastic?

Algae can potentially replace plastic in various products, such as packaging and cosmetics, through the use of sugar extracted from microalgae and marine bacteria. This can contribute to the reduction of single-use plastic and the shift towards sustainable materials.

How much does algae plastic replacements cost?

The cost of producing algae plastic replacements using a PBR is around USD 1137 per short ton of dry weight algae, which is significantly lower than the cost of producing PLA using cassava starch as a starting material, which is 2,890 USD per ton of PLA.

Is there a biodegradable alternative to plastic?

Yes, bamboo products are a biodegradable alternative to plastic that are environmentally friendly and available for various everyday uses. Consider using them for a more sustainable option.

What are 4 types of sustainable development?

The four types of sustainable development are Human, Social, Economic, and Environmental Sustainability. These pillars cover different aspects of sustainability.

How do algae contribute to plastic biodegradation?

Algae contribute to plastic biodegradation by secreting enzymes that break down plastic polymers and by colonizing on plastic surfaces to promote the breakdown of plastic.